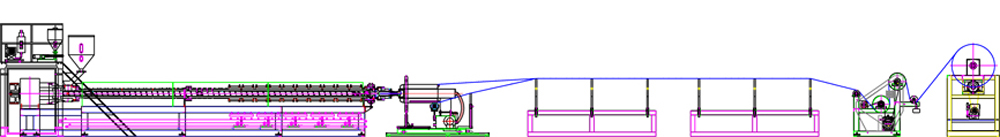

PP Foam Sheet Extrusion line is the process of manufacturing polypropylene (PP) foam sheets through a continuous extrusion method.

This is a continuous process where polypropylene (PP) resin is melted, mixed with foaming agents, and then extruded into a sheet that forms a lightweight foam material.

Polypropylene (PP) foam sheets are lightweight, flexible, and durable, with a variety of uses in industries such as packaging, automotive, construction, and insulation.

Our unique foam sheet extruder is ready to serve your needs with application-specific engineered foam including special formulations of resins and additives, extrusion techniques, sizes, shapes and configurations. Whether you need to make the material more suitable for a particular application or to meet specific standards or specifications, our unique resins, additive packages, and techniques allow to custom-engineer the foam to your unique specification.