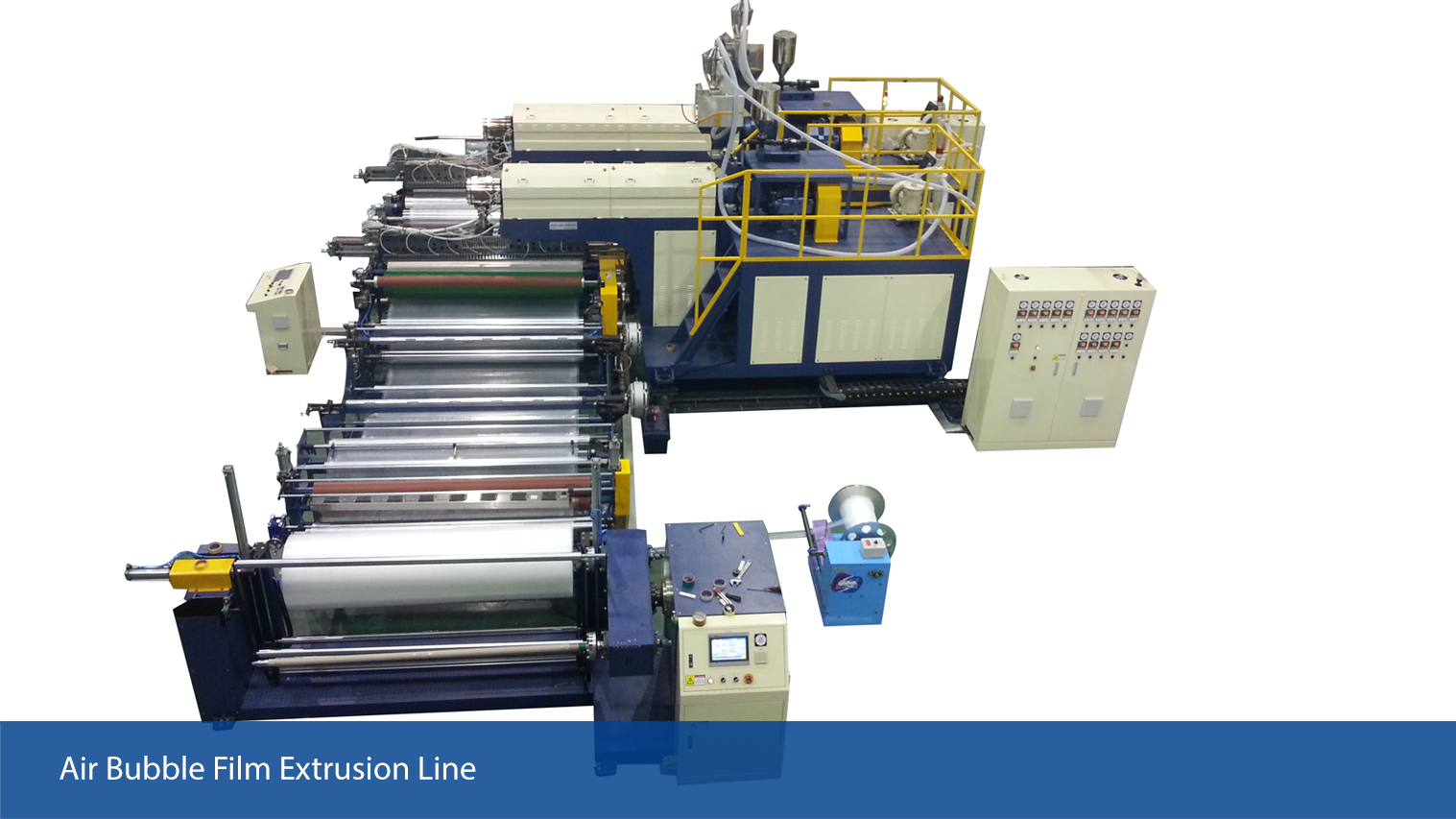

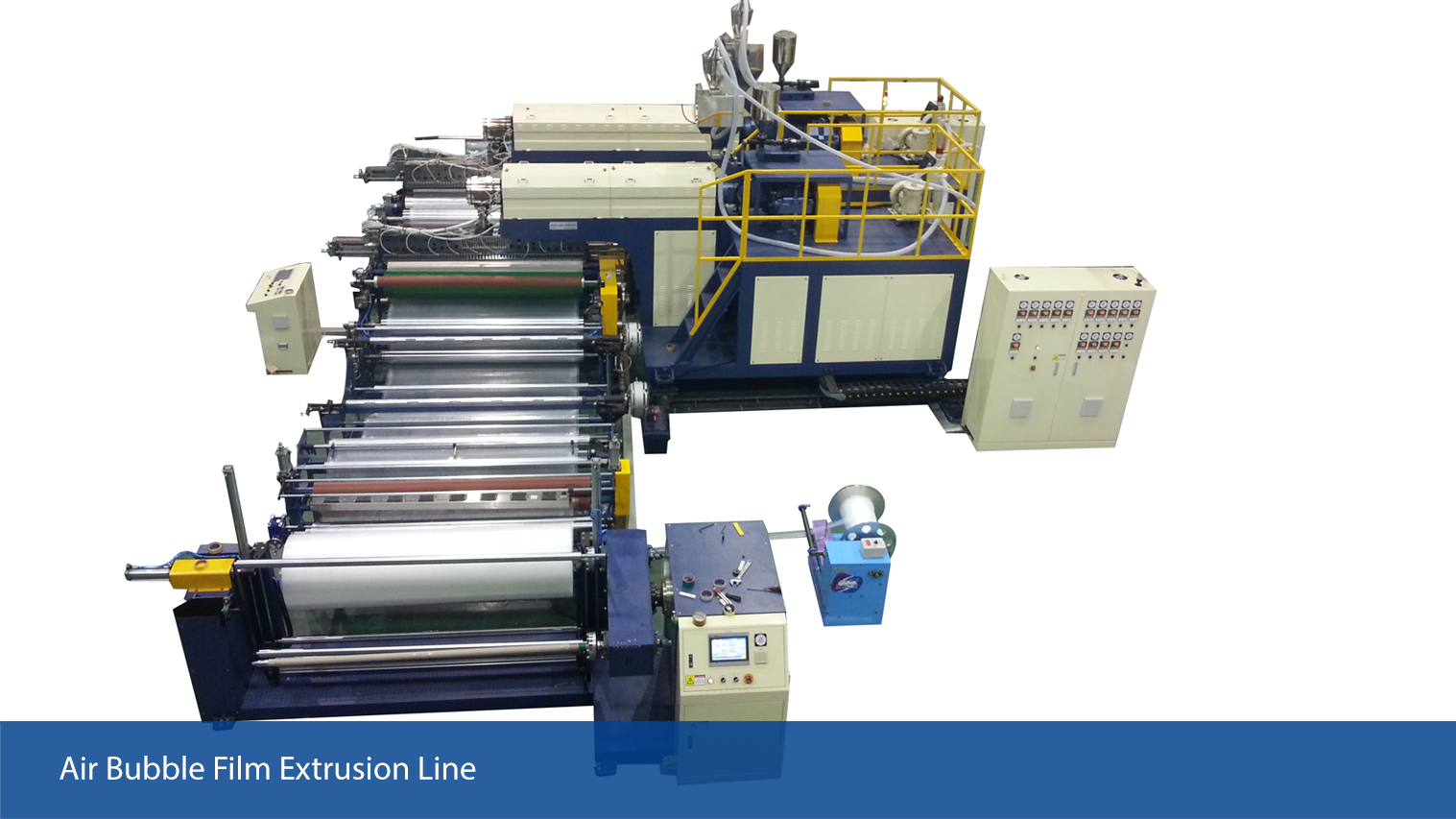

Air Bubble Film Extrusion Line is designed to produce continuous air bubble sheet by inverter Control, easy operated touch screen and automatic winding system.

The Air Bubble Film with Polyethylene is a generally used in packing, insulation and construction materials thanks to good shock absorption, corrosion resistance, impact resistance, transparency etc…

This air bubble film has the features of dampproof course, shockproof, soundproof, heat preservation effect.

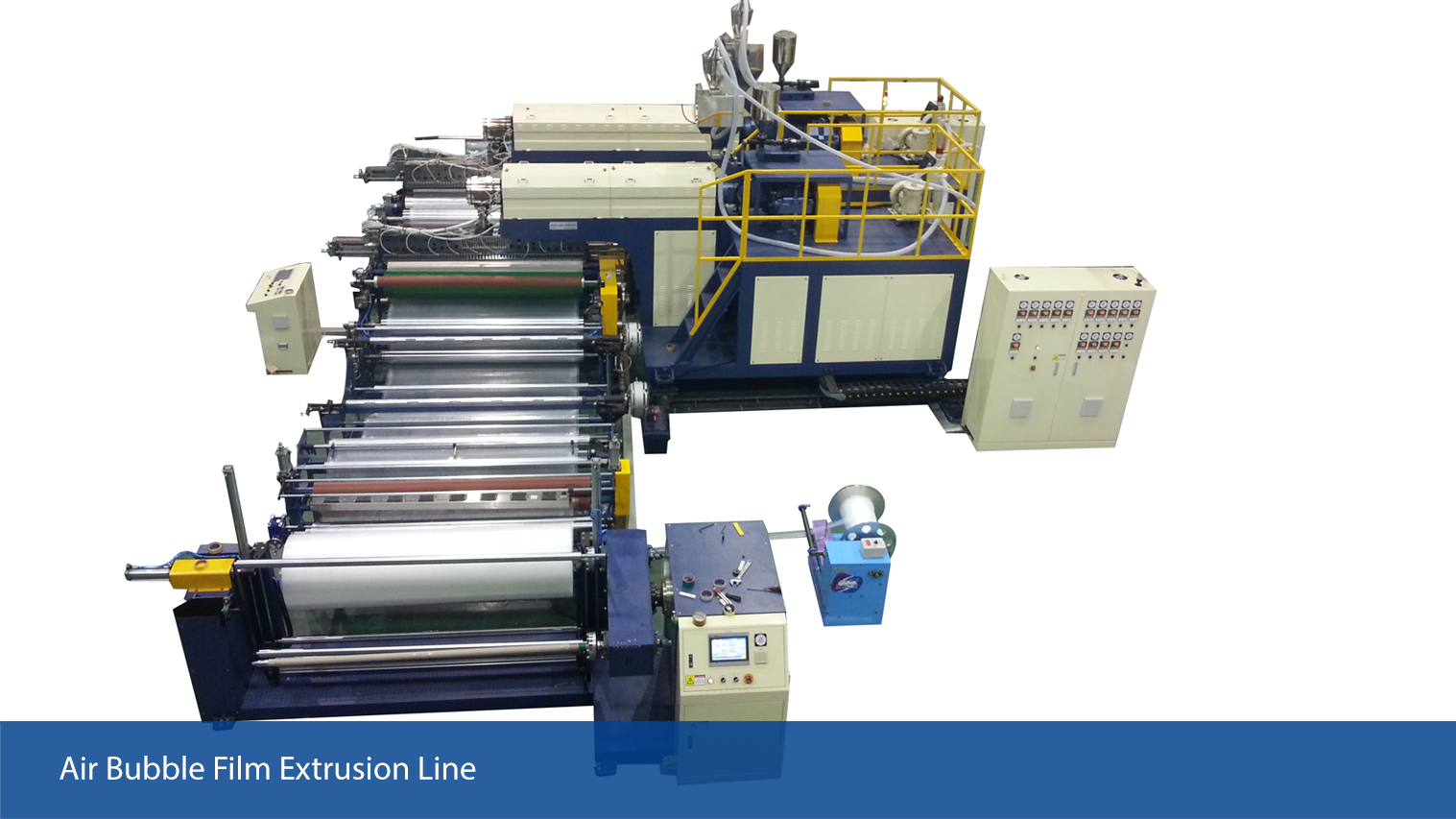

| Model No. | 100-80 | 110-90 | 130-100 |

| Layer | 2 layer, 3 layer, 5 layer | 2 layer, 3 layer, 5 layer | 2 layer, 3 layer, 5 layer |

| Width (MM) | 1000-1600 | 1000-2000 | 1000-3000 |

| Thickness (MM) | 0.02-0.08 | 0.02-0.08 | 0.04-0.08 |

| Bubble Size | Ø10×4mm Ø20×5mm |

Ø10×4mm Ø20×5mm |

Ø10×4mm Ø20×5mm |

| Capacity (kg/hr) | 250 | 320 | 450 |

| Speed (m/min) | 5-35 | 5-35 | 5-35 |