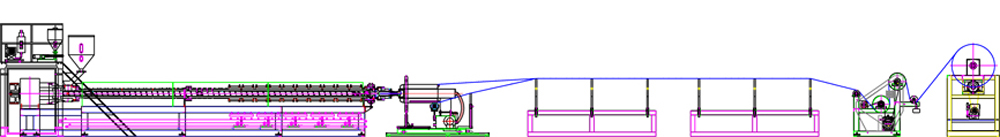

PE FOAM SHEET EXTRUSION LINE, EPE Foam Sheet Extrusion produces closed fine cell of Polyethylene foam sheet by our unique designed Screw and Barrel system using Butane, Talc master batch and GMS(Surface Active Agent) by accumulated experience and advanced technology.

Our PE Foam Sheet Extruder can be procuded upto 35mm thickness of Polyethylene foam sheet and PE Foam Board Extruder can be produced upto 100mm thickness of Polyethylene foam board directly and continuously from unique Die.

Our unique foam sheet extruder is ready to serve your needs with application-specific engineered foam including special formulations of resins and additives, extrusion techniques, sizes, shapes and configurations. Whether you need to make the material more suitable for a particular application or to meet specific standards or specifications, our unique resins, additive packages, and techniques allow to custom-engineer the foam to your unique specification.

| Model No. | RYF-105 | RYF-120 | RYF-130 | RYF-150 |

| Capacity (Kg/hr) | 80-200 | 80-250 | 80-300 | 100-350 |

| Width (MM) | 1000-2000 | 1000-2000 | 1000-2000 | 1000-2000 |

| Thickness (MM) | 0.5-10 | 0.5-12 | 0.5-15 | 1-18 |

| Density (Kg/m³) | 15-35 | 15-35 | 15-35 | 15-35 |

| Model No. | RYF-180 | RYF-200 | RYF-220 | RYF-250 |

| Capacity (Kg/hr) | 150-460 | 150-520 | 80-300 | 100-350 |

| Width (MM) | 1000-2000 | 1000-2200 | 1000-2200 | 1000-2500 |

| Thickness (MM) | 2-26 | 2-30 | 3-32 | 3-35 |

| Density (Kg/m³) | 15-35 | 13-45 | 13-45 | 13-45 |

| Model No. | RYF-130/180 | RYF-175/235 | RYF-200/250 |

| Capacity (Kg/hr) | 250-460 | 500-800 | 550-1000 |

| Width (MM) | 300-600 | 500-1000 | 500-1000 |

| Thickness (MM) | 35-50 | 35-75 | 50-100 |

| Density (Kg/m³) | 20-35 | 20-35 | 20-35 |